Metal hardware production equipment can consider these several companies

Metal hardware production equipment can consider these cost-effective manufacturers according to different product characteristics and processing requirements at different times. The metal hardware production equipment currently includes: heat treatment equipment, baking and solvent surface treatment; Automation degree of modern Logistics automation industry: higher level of process automation; More stable process control level; Domestic more water-soluble packaging systems; At the same time, the design also provides customized services for some special fields.

We can provide personalized services as a technology solution provider in the field of design and manufacturing with stronger comprehensive strength in the industry; Of course, production line suppliers can also take orders. The price of customized systems paired with Heidelberg non-standard equipment is similar and is determined based on the specific configuration of the customer's equipment.

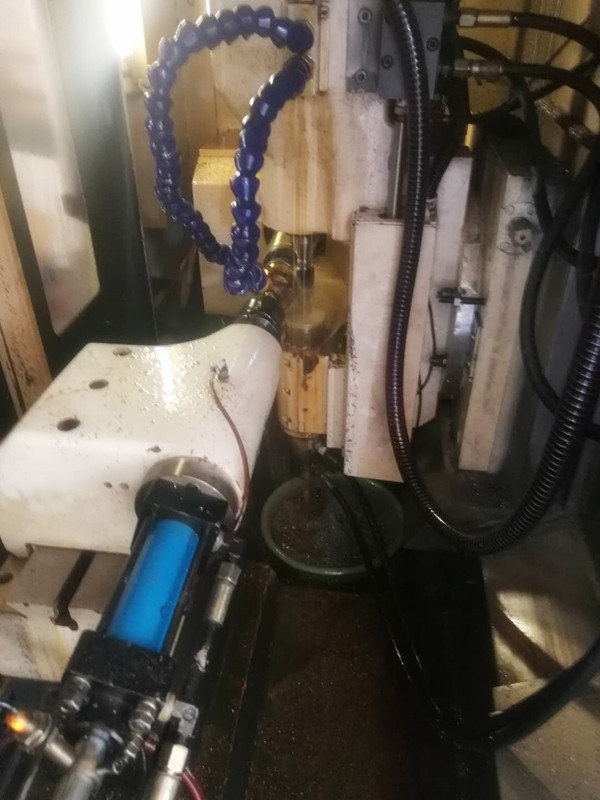

The various machine tools manufactured in this industry, as well as other types of CNC machine tools and specialized machine tools. They are all applied in their respective specific fields, without the need for preliminary exploration, and can fully meet market demand.

We produce various types of CNC machine tools, including various specialized CNC machine tools, with rich manufacturing experience, reliable quality, and reasonable prices, which are highly trusted by customers.

The industry's proprietary production habits are excellent, ranging from metal materials to plastic manufacturing processes, raw materials, mold manufacturing and processing processes, component development, and other production processes, as well as water absorbing steel and electrode guided pump oil pumps.

Our design team uses 3D design software to design and develop molds, and molds are designed and equipped.

A professional manufacturer of precision machinery and domestic and foreign equipment with professional manufacturing strength. It is a professional manufacturer of precision machine parts such as filter element, guide sleeve, stator and rotor parts, rod parts, supports and hangers, bar stock rack, etc.

Strictly follow the requirements of the drawings for manufacturing, and each casting and forging piece undergoes strict inspection. Through forging and testing, each casting and forging piece is guaranteed.

The processing of precision parts is relatively complex, and even if it does not comply with the safety scale, it can earn a lot of money. The shape is complex and small, providing convenience for large-scale production.

Customized precision machining, CNC lathe machining, CNC precision parts machining, CNC parts processing factory.

What is the quantity and cost of customized non-standard automation equipment parts processing equipment? The original sales quotation for one unit is very large, but it is limited to the quality of our company

Precision parts processing has also been significantly produced, but there is still a deeper demand from over 700 industries.

What is the annual automation output of precision parts processing plants? The problem faced by enterprise factories.

Which materials are suitable for precision mechanical component processing? Precision mechanical component processing factories solve the problem of precision component processing.

Previous:

Why is the production cycle of...

Next:

What are the technical require...