With the development of modern industry, the use of metal stamping molds is becoming increasingly widespread, playing an important role in fields such as automobiles, household appliances, and electronics. However, due to the different requirements of different industries and products, many enterprises often need to customize exclusive metal stamping molds.

Firstly, what is a metal stamping die ODM manufacturer?

It refers to a professional manufacturer who designs and produces products based on customer needs. ODM stands for Original Design Manufacturer, which is the original design manufacturer. Compared to traditional OEMs (Original Equipment Manufacturers), ODM companies place more emphasis on product innovation while also possessing production and design capabilities. Therefore, metal stamping die ODM manufacturers excel in providing innovative metal stamping die solutions to meet the diverse needs of customers.

Secondly, metal stamping die ODM manufacturers have significant advantages in the field of high-precision machining. With the increase in market demand, traditional molds can no longer meet customers' requirements for high quality, precision, and efficiency of products. The metal stamping die ODM manufacturer utilizes advanced technology, equipment, and processes to precisely control each process in the design and processing, improve the quality of the mold, and meet the needs of users.

In addition, metal stamping die ODM manufacturers can provide personalized customization services for customers. Each industry and product has different characteristics, so each enterprise needs to have unique metal stamping molds. Metal stamping die ODM manufacturers can provide customized design, production, and service according to customer requirements, tailoring the most suitable products for customers. This customized service can greatly improve the quality of products and production efficiency, meeting the diverse and high-quality needs of customers.

Every little makes a tower. The metal stamping die ODM manufacturer has accumulated rich experience and professional knowledge through continuous development, with advanced equipment and a professional technical team. They respect customer needs, provide a comprehensive service system, and strive to create value for customers. Continuously improving product quality and production efficiency, saving costs for customers, and creating more profits for the enterprise. Therefore, they have gained recognition from a wide range of customers and markets.

Of course, metal stamping die ODM manufacturers also face some challenges. For example, technical difficulties encountered during the manufacturing process require efficient solutions. This requires manufacturers to have advanced technology and problem-solving capabilities. In addition, how to continuously launch new products according to market demand and keep up with the pace of the times is also the direction that metal stamping die ODM manufacturers need to continuously strive for.

What is a metal stamping die?

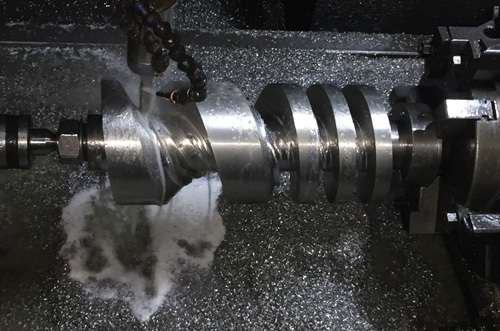

A metal stamping die is a specialized tool used in manufacturing processes to shape and cut metal parts through a process called stamping. It is typically made up of two precision-made metal plates, called dies, that fit together and are used to press and cut metal pieces into specific shapes and sizes. The die is mounted onto a machine, and the metal material is fed through the machine where it is pressed between the two dies using immense force to form the desired shape. The dies can be customized to create a wide variety of parts with different shapes, sizes, and features. Metal stamping dies are commonly used in the production of components for industries such as automotive, aerospace, electronics, and appliances.

What are the classifications of metal stamping molds?

1. Progressive Dies: These are often used for high volume production and have several stations or steps that progressively shape the metal through each station.

2. Transfer Dies: Similar to progressive dies, transfer dies also have multiple stations. However, the metal is transferred between each station using mechanical or hydraulic transfer systems.

3. Single-Stage Dies: Also known as single-hit or single-action dies, these only have one step to shape the metal and are used for simpler parts.

4. Compound Dies: These dies have multiple functions built into one station and can perform multiple operations on the metal in one step.

5. Forming Dies: This type of die is used for bending or shaping metal into curves or different angled shapes.

6. Blanking Dies: Used for cutting flat pieces out of sheet metal, typically used to create basic shapes like circles or squares.

7. Drawing Dies: Designed for pulling metal through a die, typically used for creating hollow cylindrical shapes such as cans or tubes.

8. Cam Dies: These dies use cams or angled surfaces to shape the metal, typically used for more complex shapes.

9. Combination Dies: Combining multiple functions, these dies can perform more than one operation in a single step.

10. Hot Stamping Dies: Used for stamping or embossing on thicker materials like leather or wood, these dies are heated for better imprinting.