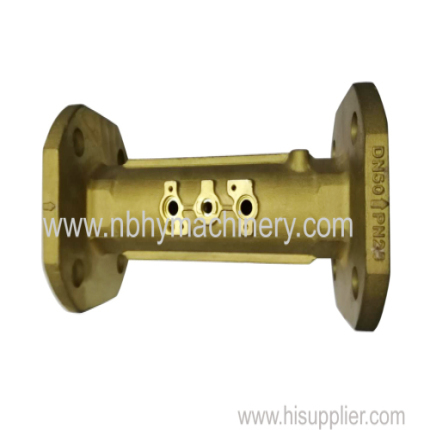

7075 Aluminium Block Cnc Machining Milling Parts

7075 aluminium block cnc machining milling parts Admin Edit

| Place of Origin: | Zhejiang, China (Mainland) |

|---|

Product Description

Hongyong Machinery Factory is a professional supplier of CNC parts,precision machining parts,forging parts,casting parts and other products. We have been committed to providing design, development, production, and services. With advanced equipment, strict testing methods, comprehensive internal control systems, and excellent after-sales service, we can provide the best OEM and ODM services according to customer requirements.

We currently have processing machinery such as Laser cutting machine,Hydraulic bending machine,Polishing machine,Hydraulic shearer,Punch press 6.3 to 160 T,Welding machine. The product can be used in industries such as hardware tool,automation industry,oil&gas exploration,medical device industry,Power and energy,home appliance,auto and motorcycle accessory. We have obtained certifications such as CE, RoHS, GS, ISO9001. As an export-oriented enterprise, we are committed to exploring markets in countries such as the United States, Canada, the United Kingdom, and Jan Mayen,Faroe Islands,Saint Lucia,Libya,Bosnia and Herzegovina,Samoa.

7075 aluminium block cnc machining milling parts technology is more accurate.Each equipment has professional worker to operate.

QC System:100% inspection according to the MIL-STD-105E, ANSI ASQC Z1.4, ABC-STD-105, BS6001, ISO 2859, DIN 40080 before shipment.

Inspection Standard: GB/T 1804-2000(Linear and angular tolerances are not noted), GB/T 1184-1996(No tolerance for shape and position), HB5800-1999(No dimensional tolerance stated), GB/T2828.1-2012(AQL).

Carton box or wood box, or per customers' requirement

T/T 30% prepaid and balance paid before shipment for the first batch order

This is our workshop and equipment

7075 aluminium block cnc machining milling parts---FAQs Guide

1.How can 7075 aluminium block cnc machining milling parts cope with applications in high vibration and impact environments, such as transportation equipment or vibrating screens?

2.What are the trends in digitization and automation of 7075 aluminium block cnc machining milling parts to improve production efficiency and quality control?

3.Are 7075 aluminium block cnc machining milling parts subjected to heat treatment or surface treatment to enhance their performance?

4.What is the data collection and monitoring function of 7075 aluminium block cnc machining milling parts to improve production traceability and control?

5.What is the corrosion resistance of 7075 aluminium block cnc machining milling parts and is it suitable for applications with corrosive media?

6.What is the relationship between the cost and performance of 7075 aluminium block cnc machining milling parts, and how to conduct a cost-benefit analysis?

7.As a 7075 aluminium block cnc machining milling parts manufacturer,can you make custom parts based on my sample?

8.Can the size and shape of 7075 aluminium block cnc machining milling parts be customized according to needs?

9.How about the maintainability and spare parts supply of 7075 aluminium block cnc machining milling parts?

10.As a 7075 aluminium block cnc machining milling parts manufacturer,OEM/ODM customer's logo printed is available?

11.Are 7075 aluminium block cnc machining milling parts suitable for applications under high temperature and pressure conditions, such as oil field equipment or chemical plants?

12.How can 7075 aluminium block cnc machining milling parts respond to voltage and power standards in different regions and countries?

1.How can 7075 aluminium block cnc machining milling parts cope with applications in high vibration and impact environments, such as transportation equipment or vibrating screens?

Reduce the cutting force to the minimum;It is to enhance the static rigidity of the tool system or fixture with the workpiece as much as possible

2.What are the trends in digitization and automation of 7075 aluminium block cnc machining milling parts to improve production efficiency and quality control?

We are a professional 7075 aluminium block cnc machining milling parts company dedicated to providing high quality products and services.

1.Improvement in accuracy and efficiency

2.The development of intelligence

3.Transformation and popularization

4.Enhance connectivity

3.Are 7075 aluminium block cnc machining milling parts subjected to heat treatment or surface treatment to enhance their performance?

Yes, 7075 aluminium block cnc machining milling parts can be subjected to heat treatment or surface treatment to enhance their performance. Heat treatment is used to alter the physical and sometimes chemical properties of a material, while surface treatment is used to improve the appearance and/or corrosion resistance of a material.

4.What is the data collection and monitoring function of 7075 aluminium block cnc machining milling parts to improve production traceability and control?

We focus on providing high 7075 aluminium block cnc machining milling parts quality products and services.

1.Collecting various parameters including machine tool feed, spindle speed, temperature, vibration, current, etc., to achieve comprehensive and accurate data collection.

2.Through real-time monitoring and control, abnormal situations during machine tool processing can be detected in a timely manner, and adjustments can be made to improve processing stability and accuracy.

5.What is the corrosion resistance of 7075 aluminium block cnc machining milling parts and is it suitable for applications with corrosive media?

The ability of metal materials to resist the corrosive damage of surrounding media is called corrosion resistance and it is suitable for applications with corrosive media.

6.What is the relationship between the cost and performance of 7075 aluminium block cnc machining milling parts, and how to conduct a cost-benefit analysis?

The processing cost varies with the type of machine, and the time required for the complete processing of any CNC machining component also plays an important role in the calculation of CNC machining cost. The longer the processing time, the higher the processing cost. The time required for the complete processing of any CNC machining component also plays an important role in the calculation of CNC machining cost. The longer the processing time, the higher the processing cost, The processing cost will also increase with the complexity of CNC machining parts, and material cost is also essential when calculating CNC machining costs

7.As a 7075 aluminium block cnc machining milling parts manufacturer,can you make custom parts based on my sample?

Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing forproduction.

8.Can the size and shape of 7075 aluminium block cnc machining milling parts be customized according to needs?

Yes, 7075 aluminium block cnc machining milling parts can be customized according to the customer's needs. CNC machining can produce parts in a variety of sizes and shapes, including complex geometries. The customer can provide a design or drawing of the desired part, and the CNC machining shop can use the design to create the part.

9.How about the maintainability and spare parts supply of 7075 aluminium block cnc machining milling parts?

When the CNC system is not in use for a long time, the maintenance work should pay attention to the following two aspects:

1.the CNC system should be regularly powered on and running idle, so that the heat from the electronic and electrical components of the CNC system can be used to dissipate the moisture inside the CNC cabinet

2.The normal supply of spare parts is a guarantee measure to ensure the normal and uninterrupted operation of the system. Our company will provide spare parts for auxiliary equipment during the warranty period and random spare parts during equipment installation and debugging

10.As a 7075 aluminium block cnc machining milling parts manufacturer,OEM/ODM customer's logo printed is available?

YES, OEM/ODM, customer's logo welcomed.

11.Are 7075 aluminium block cnc machining milling parts suitable for applications under high temperature and pressure conditions, such as oil field equipment or chemical plants?

Yes, 7075 aluminium block cnc machining milling parts can be suitable for applications under high temperature and pressure conditions. CNC machining parts can be made from a variety of materials, including metals such as stainless steel, aluminum, and titanium, which are all suitable for high temperature and pressure applications. Additionally, CNC machining parts can be designed to meet specific requirements, such as corrosion resistance, strength, and durability.

12.How can 7075 aluminium block cnc machining milling parts respond to voltage and power standards in different regions and countries?

For imported CNC machine tools and equipment, it is necessary to read the accompanying instructions clearly and connect them according to the instructions. Before powering on, it is also necessary to carefully check whether the input voltage and frequency are correct

Related Products

cheap cnc machine parts china

cheap cnc machined aluminum parts

cheap cnc machined bicycle parts

cheap cnc machined metal parts

cheap cnc machined plastic parts

cheap cnc machining aluminum parts

cheap cnc machining car parts

cheap cnc machining parts of brass

Related Links

Category: Other products