Aerospace Cnc Machined Parts

Product Description

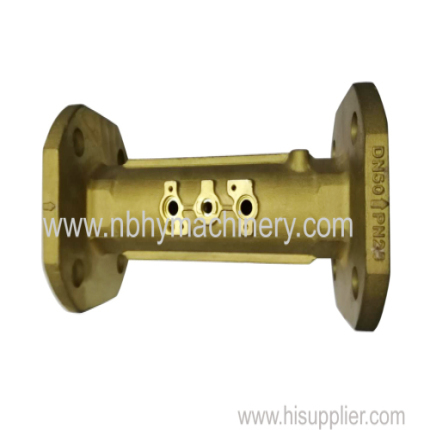

Hongyong Machinery Factory is an enterprise that produces precision machining parts,CNC parts,metal hardware,forging parts, with complete testing equipment and strong technical strength. Our products have a wide variety, excellent quality, reasonable prices, and are widely used in industries such as aerospace industry,oil&gas exploration,home appliance,automation industry,Power and energy,machinery accessory,hardware tool. We have obtained certifications such as CE, RoHS, GS, ISO9001.

Our processing methods mainly include Riveting,Tapping,Casting,Stamping,Gear cutting,Grinding,Wire EDM, etc. Having surface treatment technologies such as Anodizing,Gold plating,heat treatment,Oxidation,plating,Chrome plating,Zinc plating,Powder coating,Electrolytic polishing,Passivation,Vacuum plating,Ion nitriding. At the same time, we provide OEM services. The main export markets include North America, Western Europe, Eastern Europe, South America, Southeast Asia, East Asia, etc. Our payment methods include wire transfer, letter of credit, and payment against documents. Our goal is to continuously improve quality and pursue customer satisfaction.

aerospace cnc machined parts technology is more accurate.Each equipment has professional worker to operate.

QC System:100% inspection according to the MIL-STD-105E, ANSI ASQC Z1.4, ABC-STD-105, BS6001, ISO 2859, DIN 40080 before shipment.

Inspection Standard: GB/T 1804-2000(Linear and angular tolerances are not noted), GB/T 1184-1996(No tolerance for shape and position), HB5800-1999(No dimensional tolerance stated), GB/T2828.1-2012(AQL).

EPE foam/ Anti-Rust Paper/ Stretch Film/ Plastic bag +Carton

T/T 30% prepaid and balance paid before shipment for the first batch order

This is our workshop and equipment

aerospace cnc machined parts---FAQs Guide

1.Is aerospace cnc machined parts suitable for manufacturing parts with high safety and food labeling requirements?

2.How about the maintainability and spare parts supply of aerospace cnc machined parts?

3.How do aerospace cnc machined parts manage supply chain and inventory to ensure timely delivery and production planning?

4.How can aerospace cnc machined parts control material waste and improve resource utilization to reduce costs?

5.How do aerospace cnc machined parts handle the cutting and carving processes of materials to meet the requirements of complex parts?

6.What is the research and development capability of the factory?

7.Are there aerospace cnc machined parts suitable for parts with special shapes or complex structures?

8.How to ensure that the surface finish and quality of aerospace cnc machined parts meet the specification requirements?

9.What are the common materials used for aerospace cnc machined parts?

10.About aerospace cnc machined parts,Where can I get product&price information?

11.Are aerospace cnc machined parts suitable for applications in special environments and climatic conditions, such as in marine or desert areas?

12.What is the corrosion resistance of aerospace cnc machined parts and is it suitable for applications with corrosive media?

13.How to ensure the dimensional accuracy of aerospace cnc machined parts to meet assembly and splicing requirements?

14.What is the strength and rigidity of aerospace cnc machined parts, suitable for high load applications?

1.Is aerospace cnc machined parts suitable for manufacturing parts with high safety and food labeling requirements?

Yes, aerospace cnc machined parts can be used to manufacture parts with high safety and food labeling requirements. CNC machining is a precise and accurate process that can produce parts with tight tolerances and high levels of repeatability. This makes it ideal for producing parts with high safety and food labeling requirements.

2.How about the maintainability and spare parts supply of aerospace cnc machined parts?

When the CNC system is not in use for a long time, the maintenance work should pay attention to the following two aspects:

1.the CNC system should be regularly powered on and running idle, so that the heat from the electronic and electrical components of the CNC system can be used to dissipate the moisture inside the CNC cabinet

2.The normal supply of spare parts is a guarantee measure to ensure the normal and uninterrupted operation of the system. Our company will provide spare parts for auxiliary equipment during the warranty period and random spare parts during equipment installation and debugging

3.How do aerospace cnc machined parts manage supply chain and inventory to ensure timely delivery and production planning?

We are centered on customers and always pay attention to customers' needs for aerospace cnc machined parts products.

1. Specify the warehousing standards for components

2. Warehousing of components

3. Review of component delivery notes

4. Quality inspection and acceptance

4.How can aerospace cnc machined parts control material waste and improve resource utilization to reduce costs?

Our products & services cover a wide range of areas and meet the needs of different fields.

1.Optimize processing technology

2.Select appropriate CNC machine tools and control systems

3.Plan and manage production

4.Reduce material consumption and production costs

5.Using efficient molds and equipment

6.Improve production and management systems

5.How do aerospace cnc machined parts handle the cutting and carving processes of materials to meet the requirements of complex parts?

We operate our aerospace cnc machined parts business with integrity and honesty.

1.Cleaning and inspection process

2.Measurement process

3.Adjusting the cutting space of the tool

6.What is the research and development capability of the factory?

CNC machine tool manufacturers have innovated in the structural design of machine tools. They designed a more compact, stable, and highly rigid structure by analyzing the basic principles of mechanical cutting and the motion characteristics of machine tools. This structure can improve the rigidity and stability of the machine tool, reduce the vibration, noise, and heat generated during high-speed cutting, and thus improve the processing quality and efficiency.

7.Are there aerospace cnc machined parts suitable for parts with special shapes or complex structures?

Yes, CNC machining is suitable for parts with special shapes or complex structures. CNC machining is a subtractive manufacturing process that uses computer-controlled cutting tools to remove material from a block of material to create a part with a specific shape and size. CNC machining is ideal for producing parts with complex geometries and intricate details that would be difficult or impossible to produce with traditional manufacturing methods.

8.How to ensure that the surface finish and quality of aerospace cnc machined parts meet the specification requirements?

We are centered on customers and always pay attention to customers' needs for aerospace cnc machined parts products.

1.selecting appropriate cutting parameters is the key to controlling surface roughness and smoothness

2.the selection and grinding of cutting tools also play an important role in controlling surface roughness and smoothness

9.What are the common materials used for aerospace cnc machined parts?

Titanium, Aluminum, Stainless Steel, Copper/Brass, Iron, any types of alloy

10.About aerospace cnc machined parts,Where can I get product&price information?

Send us e-mail , we will contact you as we receive your mail.

11.Are aerospace cnc machined parts suitable for applications in special environments and climatic conditions, such as in marine or desert areas?

Yes, aerospace cnc machined parts can be suitable for applications in special environments and climatic conditions. Depending on the material used, CNC machining parts can be designed to be corrosion-resistant, heat-resistant, and/or waterproof. Additionally, CNC machining parts can be designed to be lightweight and durable, making them suitable for use in harsh environments.

12.What is the corrosion resistance of aerospace cnc machined parts and is it suitable for applications with corrosive media?

The ability of metal materials to resist the corrosive damage of surrounding media is called corrosion resistance and it is suitable for applications with corrosive media.

13.How to ensure the dimensional accuracy of aerospace cnc machined parts to meet assembly and splicing requirements?

We have a first -class management team, and we pay attention to teamwork to achieve common goals.

1. Use high-precision processing equipment and tools.

2. Strictly control the processing process.

3. Use appropriate testing for measurement work.

4. Conduct pre assembly coordination testing and adjustments

14.What is the strength and rigidity of aerospace cnc machined parts, suitable for high load applications?

The ability of metal materials to resist elastic deformation under stress and The ability of metal materials to resist plastic deformation and fracture under external forces.

Related Products

carbon steel cnc machined part

carbon steel cnc machining part

cast cnc machined parts production

cast iron cnc casting machining parts

casting cnc stainless steel machining part

cheap aluminum cnc machining parts

cheap cast cnc machined parts

cheap cnc machine parts china

Related Links

Category: Other products