All Parts Of A Cnc Machine

Product Description

Ningbo Yinzhou Hongyong Machinery Factory is a CNC manufacturer proudly producing different kinds of parts that are made in China.We have a customer driven focus and commitment to on-time delivery of top-quality products.We have decades years of experience in metal parts related products and can customize parts based on customer provided drawings.

Our precision machinery includes Polishing machine,Milling machine,Assembly line,Laser cutting machine,Hydraulic shearer,Punch press 6.3 to 160 T and others. It can process metal hardware,casting parts,CNC parts,precision machining parts,etc, and can be widely used for medical device industry,home appliance,Power and energy,hardware tool,oil&gas exploration,machinery accessory,aerospace industry and other industry. We are a professional OEM/ODM manufacturer with over 12 years of experience. Our products have competitive prices, high precision, high quality, and tight tolerances.

all parts of a cnc machine technology is more accurate.Each equipment has professional worker to operate.

Quality Control System: Incoming inspection, process inspection, finished product inspection, delivery inspection.

Inspection Standard: GB/T 1804-2000(Linear and angular tolerances are not noted), GB/T 1184-1996(No tolerance for shape and position), HB5800-1999(No dimensional tolerance stated), GB/T2828.1-2012(AQL).

EPE foam/ Anti-Rust Paper/ Stretch Film/ Plastic bag +Carton

T/T 30% prepaid and balance paid before shipment for the first batch order

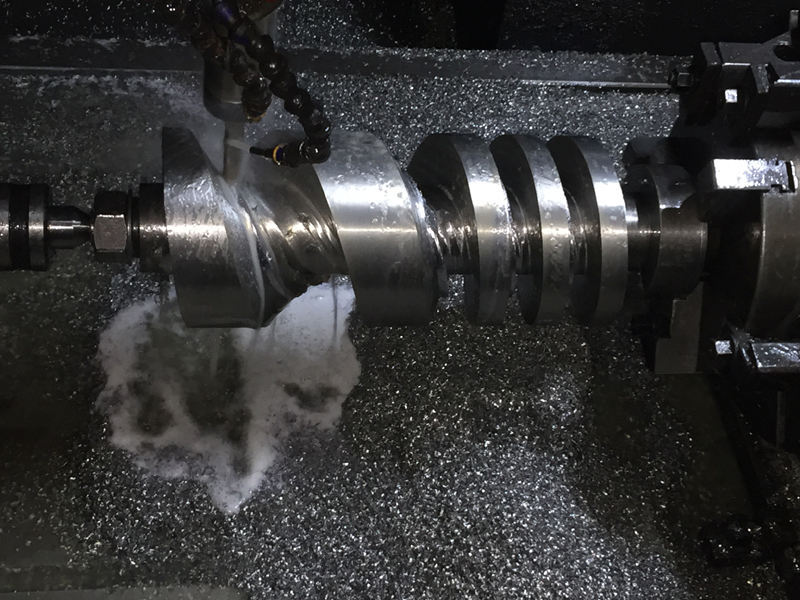

This is our workshop and equipment

all parts of a cnc machine---FAQs Guide

1.What are the product skill training options?

2.Are all parts of a cnc machine subjected to heat treatment or surface treatment to enhance their performance?

3.How do all parts of a cnc machine handle the extrusion and removal processes of materials to meet design requirements?

4.As a all parts of a cnc machine manufacturer,what is the material?

5.Is all parts of a cnc machine suitable for manufacturing parts required by special industry standards and regulations, such as aerospace?

6.What is the production capacity of all parts of a cnc machine, and can they meet the needs of large-scale production?

7.About all parts of a cnc machine,can I get a quote without drawings?

8.Is all parts of a cnc machine suitable for applications in high-speed motion and vibration environments, such as automotive engines or machine tools?

9.How can all parts of a cnc machine cope with applications in high vibration and impact environments, such as transportation equipment or vibrating screens?

10.How to ensure that the surface finish and quality of all parts of a cnc machine meet the specification requirements?

11.How can all parts of a cnc machine adapt to different hardness and processing requirements of materials, such as steel or plastic?

12.What is the accuracy and repeatability of all parts of a cnc machine?

1.What are the product skill training options?

Our training options include:

1. Basic knowledge of CNC machining

2. CNC programming technology

3. Machining process and fixture design

4. Operating skills of CNC machining centers

5. Troubleshooting and maintenance

6. Safety operation and quality control

7. Application cases and practical operations

2.Are all parts of a cnc machine subjected to heat treatment or surface treatment to enhance their performance?

Yes, all parts of a cnc machine can be subjected to heat treatment or surface treatment to enhance their performance. Heat treatment is used to alter the physical and sometimes chemical properties of a material, while surface treatment is used to improve the appearance and/or corrosion resistance of a material.

3.How do all parts of a cnc machine handle the extrusion and removal processes of materials to meet design requirements?

all parts of a cnc machine use a variety of tools and techniques to handle the extrusion and removal processes of materials. Depending on the material and design requirements, the machining process may involve cutting, drilling, milling, grinding, and other operations. For example, a CNC milling machine can be used to cut away excess material from a workpiece, while a CNC lathe can be used to shape and form the material. Additionally, CNC machining can be used to create complex shapes and features, such as threads, grooves, and other intricate details.

4.As a all parts of a cnc machine manufacturer,what is the material?

Plastics we can manufacture are ABS, PC, PP, PA, PA+GF, PTFE etc, metals are aluminum, stainless steel, brass, copper etc.

5.Is all parts of a cnc machine suitable for manufacturing parts required by special industry standards and regulations, such as aerospace?

Yes, all parts of a cnc machine are suitable for manufacturing parts required by special industry standards and regulations, such as aerospace. CNC machining is a precise and accurate process that can produce parts with tight tolerances and complex geometries. It is also capable of producing parts with high levels of repeatability and consistency, which is essential for parts used in the aerospace industry.

6.What is the production capacity of all parts of a cnc machine, and can they meet the needs of large-scale production?

all parts of a cnc machine are mainly suitable for the following occasions: batch production: CNC lathes are suitable for large-scale and continuous batch production.

7.About all parts of a cnc machine,can I get a quote without drawings?

Sure, we appreciate to receive your samples, pictures or drafts with detailed dimensions for accurate quotation.

8.Is all parts of a cnc machine suitable for applications in high-speed motion and vibration environments, such as automotive engines or machine tools?

Yes, all parts of a cnc machine are suitable for applications in high-speed motion and vibration environments. CNC machining parts are designed to be precise and durable, making them ideal for use in high-speed and vibration environments. CNC machining parts are also able to withstand high temperatures and pressures, making them suitable for use in automotive engines and machine tools.

9.How can all parts of a cnc machine cope with applications in high vibration and impact environments, such as transportation equipment or vibrating screens?

Reduce the cutting force to the minimum;It is to enhance the static rigidity of the tool system or fixture with the workpiece as much as possible

10.How to ensure that the surface finish and quality of all parts of a cnc machine meet the specification requirements?

We are centered on customers and always pay attention to customers' needs for all parts of a cnc machine products.

1.selecting appropriate cutting parameters is the key to controlling surface roughness and smoothness

2.the selection and grinding of cutting tools also play an important role in controlling surface roughness and smoothness

11.How can all parts of a cnc machine adapt to different hardness and processing requirements of materials, such as steel or plastic?

During the machining process, attention should always be paid to the wear of the cutting tools, and severely worn cutting tools should be replaced in a timely manner to ensure the machining effect.

When adjusting cutting parameters, comprehensive consideration should be given to factors such as material hardness, cutting depth, and the shape of the workpiece being processed to achieve the best effect.

12.What is the accuracy and repeatability of all parts of a cnc machine?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance.

1.The smaller the difference between the actual position of parts or tools and the standard position (theoretical position, ideal position), the higher the accuracy. It is a prerequisite for ensuring the machining accuracy of parts.

2.The consistency of continuous results obtained by machining a batch of parts under the same conditions (on the same CNC machine tool, with different operating methods and using the same part program).

Related Products

bulk cnc machined metal parts

bulk cnc machining aluminum part

bushings cnc machining stainless steel parts

camera cnc machining parts

camera on cnc machine measure part

car cnc machining parts

car parts machining custom cnc

carbon fiber parts cnc machining

Related Links

Category: Other products