Aluminium Cnc Machine Parts

Product Description

Hongyong Machinery Factory is a professional supplier of forging parts,casting parts,metal hardware,CNC parts and other products. We have been committed to providing design, development, production, and services. With advanced equipment, strict testing methods, comprehensive internal control systems, and excellent after-sales service, we can provide the best OEM and ODM services according to customer requirements.

We currently have processing machinery such as Milling machine,Polishing machine,Hydraulic bending machine,Welding machine,Laser cutting machine,Hydraulic shearer. The product can be used in industries such as medical device industry,auto and motorcycle accessory,machinery accessory,aerospace industry,home appliance,hardware tool,oil&gas exploration. We have obtained certifications such as CE, RoHS, GS, ISO9001. As an export-oriented enterprise, we are committed to exploring markets in countries such as the United States, Canada, the United Kingdom, and Brunei,Botswana,Latvia,Denmark,Spratly Islands.

aluminium cnc machine parts:

Customized Design

Sample Order Accepted

Short Delivery time

Competitive Prices

Long time quality Insurance

Professional after-sale services

QC System:100% inspection according to the MIL-STD-105E, ANSI ASQC Z1.4, ABC-STD-105, BS6001, ISO 2859, DIN 40080 before shipment.

Inspection Standard: GB/T 1804-2000(Linear and angular tolerances are not noted), GB/T 1184-1996(No tolerance for shape and position), HB5800-1999(No dimensional tolerance stated), GB/T2828.1-2012(AQL).

Carton box or wood box, or per customers' requirement

30% deposit ,70% payment aganist B/L

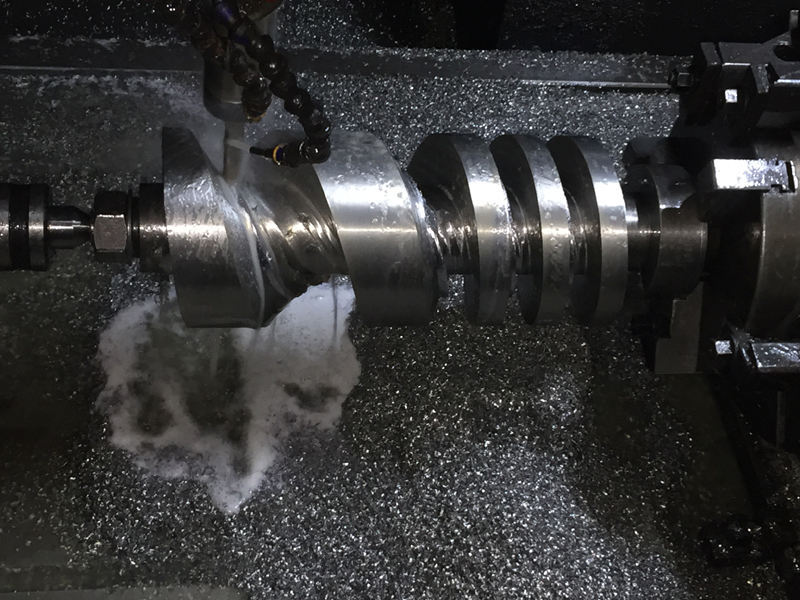

This is our workshop and equipment

aluminium cnc machine parts---FAQs Guide

1.How do aluminium cnc machine parts handle the extrusion and removal processes of materials to meet design requirements?

2.What is the strength and rigidity of aluminium cnc machine parts, suitable for high load applications?

3.What are the advantages of aluminium cnc machine parts?

4.How can aluminium cnc machine parts adapt to different hardness and processing requirements of materials, such as steel or plastic?

5.What is the machining accuracy and repeatability of aluminium cnc machine parts to achieve assembly and interchangeability?

6.Are aluminium cnc machine parts suitable for applications under high temperature and pressure conditions, such as oil field equipment or chemical plants?

7.How do aluminium cnc machine parts manage supply chain and inventory to ensure timely delivery and production planning?

8.How to ensure the dimensional accuracy of aluminium cnc machine parts to meet assembly and splicing requirements?

9.Is aluminium cnc machine parts suitable for manufacturing parts required by special industry standards and regulations, such as aerospace?

10.How can aluminium cnc machine parts respond to voltage and power standards in different regions and countries?

11.As a aluminium cnc machine parts manufacturer,can you provide one-stop service including of material,processing,finish,assembly etc?

12.How can aluminium cnc machine parts control material waste and improve resource utilization to reduce costs?

13.How do aluminium cnc machine parts handle the cutting and carving processes of materials to meet the requirements of complex parts?

14.What are the trends in digitization and automation of aluminium cnc machine parts to improve production efficiency and quality control?

15.What are the common materials used for aluminium cnc machine parts?

1.How do aluminium cnc machine parts handle the extrusion and removal processes of materials to meet design requirements?

aluminium cnc machine parts use a variety of tools and techniques to handle the extrusion and removal processes of materials. Depending on the material and design requirements, the machining process may involve cutting, drilling, milling, grinding, and other operations. For example, a CNC milling machine can be used to cut away excess material from a workpiece, while a CNC lathe can be used to shape and form the material. Additionally, CNC machining can be used to create complex shapes and features, such as threads, grooves, and other intricate details.

2.What is the strength and rigidity of aluminium cnc machine parts, suitable for high load applications?

The ability of metal materials to resist elastic deformation under stress and The ability of metal materials to resist plastic deformation and fracture under external forces.

3.What are the advantages of aluminium cnc machine parts?

We have advanced production equipment and technology to meet the needs of customers, and can provide customers with high quality, low priced aluminium cnc machine parts products.

1. Highly precise

2. High efficiency

3. Strong flexibility

4. Simple operation

5. Stable quality

6. High productivity

7. Wide processing range

8. Cost saving

9. Reliable and stable

4.How can aluminium cnc machine parts adapt to different hardness and processing requirements of materials, such as steel or plastic?

During the machining process, attention should always be paid to the wear of the cutting tools, and severely worn cutting tools should be replaced in a timely manner to ensure the machining effect.

When adjusting cutting parameters, comprehensive consideration should be given to factors such as material hardness, cutting depth, and the shape of the workpiece being processed to achieve the best effect.

5.What is the machining accuracy and repeatability of aluminium cnc machine parts to achieve assembly and interchangeability?

For machine tools with general machining requirements, the repeated positioning accuracy is generally required to be less than or equal to 0.005mm.

6.Are aluminium cnc machine parts suitable for applications under high temperature and pressure conditions, such as oil field equipment or chemical plants?

Yes, aluminium cnc machine parts can be suitable for applications under high temperature and pressure conditions. CNC machining parts can be made from a variety of materials, including metals such as stainless steel, aluminum, and titanium, which are all suitable for high temperature and pressure applications. Additionally, CNC machining parts can be designed to meet specific requirements, such as corrosion resistance, strength, and durability.

7.How do aluminium cnc machine parts manage supply chain and inventory to ensure timely delivery and production planning?

We are centered on customers and always pay attention to customers' needs for aluminium cnc machine parts products.

1. Specify the warehousing standards for components

2. Warehousing of components

3. Review of component delivery notes

4. Quality inspection and acceptance

8.How to ensure the dimensional accuracy of aluminium cnc machine parts to meet assembly and splicing requirements?

We have a first -class management team, and we pay attention to teamwork to achieve common goals.

1. Use high-precision processing equipment and tools.

2. Strictly control the processing process.

3. Use appropriate testing for measurement work.

4. Conduct pre assembly coordination testing and adjustments

9.Is aluminium cnc machine parts suitable for manufacturing parts required by special industry standards and regulations, such as aerospace?

Yes, aluminium cnc machine parts are suitable for manufacturing parts required by special industry standards and regulations, such as aerospace. CNC machining is a precise and accurate process that can produce parts with tight tolerances and complex geometries. It is also capable of producing parts with high levels of repeatability and consistency, which is essential for parts used in the aerospace industry.

10.How can aluminium cnc machine parts respond to voltage and power standards in different regions and countries?

For imported CNC machine tools and equipment, it is necessary to read the accompanying instructions clearly and connect them according to the instructions. Before powering on, it is also necessary to carefully check whether the input voltage and frequency are correct

11.As a aluminium cnc machine parts manufacturer,can you provide one-stop service including of material,processing,finish,assembly etc?

Yes,we can.

12.How can aluminium cnc machine parts control material waste and improve resource utilization to reduce costs?

Our products & services cover a wide range of areas and meet the needs of different fields.

1.Optimize processing technology

2.Select appropriate CNC machine tools and control systems

3.Plan and manage production

4.Reduce material consumption and production costs

5.Using efficient molds and equipment

6.Improve production and management systems

13.How do aluminium cnc machine parts handle the cutting and carving processes of materials to meet the requirements of complex parts?

We operate our aluminium cnc machine parts business with integrity and honesty.

1.Cleaning and inspection process

2.Measurement process

3.Adjusting the cutting space of the tool

14.What are the trends in digitization and automation of aluminium cnc machine parts to improve production efficiency and quality control?

We are a professional aluminium cnc machine parts company dedicated to providing high quality products and services.

1.Improvement in accuracy and efficiency

2.The development of intelligence

3.Transformation and popularization

4.Enhance connectivity

15.What are the common materials used for aluminium cnc machine parts?

Titanium, Aluminum, Stainless Steel, Copper/Brass, Iron, any types of alloy

Related Products

brass parts cnc machining

brother cnc machine parts

brother cnc milling machines parts

building a cnc machine part 1

building a cnc machine part 6

building cnc machine part 3

bulk cnc machined metal parts

bulk cnc machining aluminum part

Related Links

Category: Other products