Cheap Pet Parts Cnc Machining

Product Description

Hongyong Machinery is an enterprise that produces forging parts,casting parts,CNC parts,precision machining parts, with complete testing equipment and strong technical strength. Our products have a wide variety, excellent quality, reasonable prices, and are widely used in industries such as auto and motorcycle accessory,aerospace industry,oil&gas exploration,medical device industry,hardware tool,Power and energy,machinery accessory. We have obtained certifications such as CE, RoHS, GS, ISO9001.

Our processing methods mainly include Tapping,Gear cutting,Milling,Casting,Forging,Grinding,Wire EDM, etc. Having surface treatment technologies such as Vacuum plating,Chrome plating,Electroplating,Ion nitriding,polishing,plating,Zinc plating,Electrolytic polishing,hardening,Passivation,Thermal treatment,Sandblasting,Gold plating. At the same time, we provide OEM services. The main export markets include North America, Western Europe, Eastern Europe, South America, Southeast Asia, East Asia, etc. Our payment methods include wire transfer, letter of credit, and payment against documents. Our goal is to continuously improve quality and pursue customer satisfaction.

cheap pet parts cnc machining:

Machine: 3/4/5 axis CNC Machining Center

Roughness: Ra0.2-Ra3.2

Tolerance: 0.005~0.05mm or refer to drawings strictly

Main Process: Turning / Milling

QC System:100% inspection according to the MIL-STD-105E, ANSI ASQC Z1.4, ABC-STD-105, BS6001, ISO 2859, DIN 40080 before shipment.

Inspection Standard: GB/T 1804-2000(Linear and angular tolerances are not noted), GB/T 1184-1996(No tolerance for shape and position), HB5800-1999(No dimensional tolerance stated), GB/T2828.1-2012(AQL).

Carton box or wood box, or per customers' requirement

T/T 30% prepaid and balance paid before shipment for the first batch order

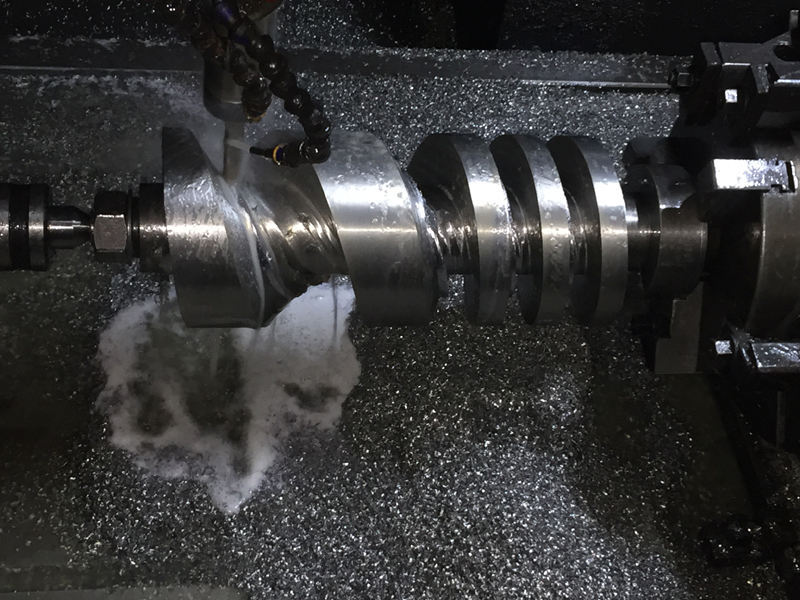

This is our workshop and equipment

cheap pet parts cnc machining---FAQs Guide

1.How about the maintainability and spare parts supply of cheap pet parts cnc machining?

2.Are there cheap pet parts cnc machining suitable for parts with special shapes or complex structures?

3.How can cheap pet parts cnc machining control material waste and improve resource utilization to reduce costs?

4.How can we ensure our information should not let third party to see our design?

5.What is the role of CNC machining parts in the manufacturing industry?

6.Are cheap pet parts cnc machining suitable for applications in special environments and climatic conditions, such as in marine or desert areas?

7.What are the advantages of cheap pet parts cnc machining?

8.How does the selection of machine tools and cutting tools for cheap pet parts cnc machining affect machining speed and quality?

9.What is the production capacity of cheap pet parts cnc machining, and can they meet the needs of large-scale production?

10.What is the corrosion resistance of cheap pet parts cnc machining and is it suitable for applications with corrosive media?

11.What is the relationship between the cost and performance of cheap pet parts cnc machining, and how to conduct a cost-benefit analysis?

12.How do cheap pet parts cnc machining handle the cutting and carving processes of materials to meet the requirements of complex parts?

13.What is the cleaning and maintenance process for cheap pet parts cnc machining to ensure equipment hygiene and performance?

1.How about the maintainability and spare parts supply of cheap pet parts cnc machining?

When the CNC system is not in use for a long time, the maintenance work should pay attention to the following two aspects:

1.the CNC system should be regularly powered on and running idle, so that the heat from the electronic and electrical components of the CNC system can be used to dissipate the moisture inside the CNC cabinet

2.The normal supply of spare parts is a guarantee measure to ensure the normal and uninterrupted operation of the system. Our company will provide spare parts for auxiliary equipment during the warranty period and random spare parts during equipment installation and debugging

2.Are there cheap pet parts cnc machining suitable for parts with special shapes or complex structures?

Yes, CNC machining is suitable for parts with special shapes or complex structures. CNC machining is a subtractive manufacturing process that uses computer-controlled cutting tools to remove material from a block of material to create a part with a specific shape and size. CNC machining is ideal for producing parts with complex geometries and intricate details that would be difficult or impossible to produce with traditional manufacturing methods.

3.How can cheap pet parts cnc machining control material waste and improve resource utilization to reduce costs?

Our products & services cover a wide range of areas and meet the needs of different fields.

1.Optimize processing technology

2.Select appropriate CNC machine tools and control systems

3.Plan and manage production

4.Reduce material consumption and production costs

5.Using efficient molds and equipment

6.Improve production and management systems

4.How can we ensure our information should not let third party to see our design?

We are willing to sign NDA effect by customer side local law and promising to keep customers data in high confidential level.

5.What is the role of CNC machining parts in the manufacturing industry?

Improving machining accuracy and quality,Improve production efficiency and efficiency

6.Are cheap pet parts cnc machining suitable for applications in special environments and climatic conditions, such as in marine or desert areas?

Yes, cheap pet parts cnc machining can be suitable for applications in special environments and climatic conditions. Depending on the material used, CNC machining parts can be designed to be corrosion-resistant, heat-resistant, and/or waterproof. Additionally, CNC machining parts can be designed to be lightweight and durable, making them suitable for use in harsh environments.

7.What are the advantages of cheap pet parts cnc machining?

We have advanced production equipment and technology to meet the needs of customers, and can provide customers with high quality, low priced cheap pet parts cnc machining products.

1. Highly precise

2. High efficiency

3. Strong flexibility

4. Simple operation

5. Stable quality

6. High productivity

7. Wide processing range

8. Cost saving

9. Reliable and stable

8.How does the selection of machine tools and cutting tools for cheap pet parts cnc machining affect machining speed and quality?

We have been working hard to improve service quality and meet customer needs.

1.Ensure the selection of appropriate cutting tools, and determine the type and specifications of the cutting tools based on the processing materials and requirements. Regularly inspect and replace severely worn tools to maintain their sharpness and work efficiency

2.Ensure that cutting parameters (such as cutting speed, feed rate, and cutting depth) are set reasonably to adapt to different machining tasks and materials

3.The fixation of the tool and the clamping state of the workpiece also have an impact on the tool speed

4.Regular maintenance and upkeep of CNC machine tools is also crucial for adjusting tool speed

9.What is the production capacity of cheap pet parts cnc machining, and can they meet the needs of large-scale production?

cheap pet parts cnc machining are mainly suitable for the following occasions: batch production: CNC lathes are suitable for large-scale and continuous batch production.

10.What is the corrosion resistance of cheap pet parts cnc machining and is it suitable for applications with corrosive media?

The ability of metal materials to resist the corrosive damage of surrounding media is called corrosion resistance and it is suitable for applications with corrosive media.

11.What is the relationship between the cost and performance of cheap pet parts cnc machining, and how to conduct a cost-benefit analysis?

The processing cost varies with the type of machine, and the time required for the complete processing of any CNC machining component also plays an important role in the calculation of CNC machining cost. The longer the processing time, the higher the processing cost. The time required for the complete processing of any CNC machining component also plays an important role in the calculation of CNC machining cost. The longer the processing time, the higher the processing cost, The processing cost will also increase with the complexity of CNC machining parts, and material cost is also essential when calculating CNC machining costs

12.How do cheap pet parts cnc machining handle the cutting and carving processes of materials to meet the requirements of complex parts?

We operate our cheap pet parts cnc machining business with integrity and honesty.

1.Cleaning and inspection process

2.Measurement process

3.Adjusting the cutting space of the tool

13.What is the cleaning and maintenance process for cheap pet parts cnc machining to ensure equipment hygiene and performance?

We are centered on customers and always pay attention to customers' needs for cheap pet parts cnc machining products.

1.Strictly follow the operating rules

2.Preventing overheating of CNC devices

3.Regularly monitor the grid voltage of CNC devices

4.Prevent dust from entering the CNC device 4Regular inspection and replacement of storage batteries.

5.Maintenance of CNC systems when not in use for a long time

Related Products

4 axis cnc machining aluminum parts

4 axis cnc machining parts

4 axis cnc milling machine parts

5 axis car lathe parts cnc machining

5 axis cnc machine gun parts

5 axis cnc machine parts

5 axis cnc machined part

5 axis cnc machined parts

Related Links

Category: Other products