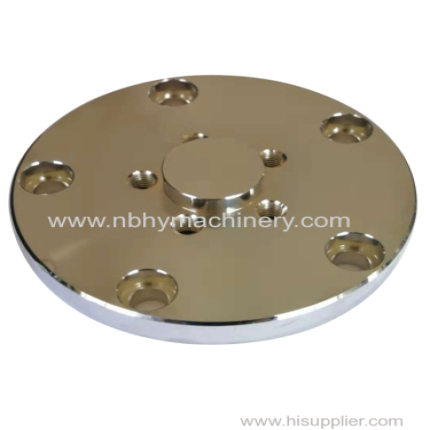

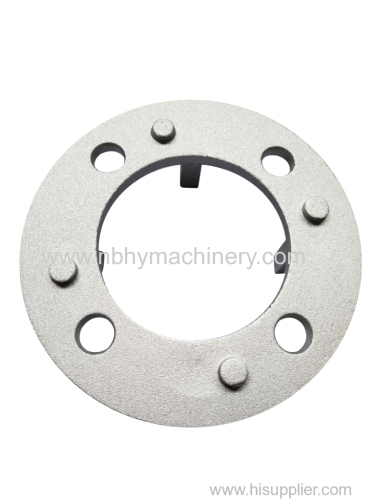

China Aluminum Parts Cnc Machining

Product Description

Ningbo Yinzhou Hongyong Machinery Factory located in ningbo, is a professional service precision metal and plastic parts manufacturer, we have casting parts,forging parts,precision machining parts,metal hardware,etc.At the same time, we also have a long-term cooperative surface treatment,spining and stamping etc.plant.Our processing methods include: Milling,Wire EDM,CNC Turning,Stamping,Gear cutting,Drilling,Riveting, etc. Can handle materials such as Alloy,Steel Alloys,any types of alloy,Carbon steel,Stainless Steel,Titanium,Cold rolled sheet,Brass,Nylon,Copper,Iron,Chrome steel.

We are committed to offer high tech, precision, good quality products to our customers at competitive price. All of them are manufactured in our plant which can be controlled quality well. We believe honesty and customer service are the foundation of a successful business.We design, manufacture and assemble all kinds of different metal and plastic parts according to designs or drawings and requirements from customers.We have obtained CE, RoHS, GS, ISO9001 and other certifications.

china aluminum parts cnc machining:Custom Turning Machining Spare Part CNC Machined Parts

Quality Control System: Incoming inspection, process inspection, finished product inspection, delivery inspection.

Inspection Standard: GB/T 1804-2000(Linear and angular tolerances are not noted), GB/T 1184-1996(No tolerance for shape and position), HB5800-1999(No dimensional tolerance stated), GB/T2828.1-2012(AQL).

Carton box or wood box, or per customers' requirement

T/T 30% prepaid and balance paid before shipment for the first batch order

This is our workshop and equipment

china aluminum parts cnc machining---FAQs Guide

1.Is china aluminum parts cnc machining suitable for manufacturing parts with high safety and food labeling requirements?

2.How about the maintainability and spare parts supply of china aluminum parts cnc machining?

3.How do china aluminum parts cnc machining handle the cutting and carving processes of materials to meet the requirements of complex parts?

4.How can china aluminum parts cnc machining cope with the manufacturing of non-standard or complex workpieces, such as reverse engineering or special shapes?

5.How to ensure the dimensional accuracy of china aluminum parts cnc machining to meet assembly and splicing requirements?

6.What is the accuracy and repeatability of china aluminum parts cnc machining?

7.How can china aluminum parts cnc machining respond to voltage and power standards in different regions and countries?

8.What is the research and development capability of the factory?

9.How does the manufacturing process and process of china aluminum parts cnc machining affect their quality and accuracy?

10.How can china aluminum parts cnc machining adapt to different hardness and processing requirements of materials, such as steel or plastic?

11.How can we ensure our information should not let third party to see our design?

12.How can china aluminum parts cnc machining cope with applications in high vibration and impact environments, such as transportation equipment or vibrating screens?

13.What is the production capacity of china aluminum parts cnc machining, and can they meet the needs of large-scale production?

14.What is the corrosion resistance of china aluminum parts cnc machining and is it suitable for applications with corrosive media?

1.Is china aluminum parts cnc machining suitable for manufacturing parts with high safety and food labeling requirements?

Yes, china aluminum parts cnc machining can be used to manufacture parts with high safety and food labeling requirements. CNC machining is a precise and accurate process that can produce parts with tight tolerances and high levels of repeatability. This makes it ideal for producing parts with high safety and food labeling requirements.

2.How about the maintainability and spare parts supply of china aluminum parts cnc machining?

When the CNC system is not in use for a long time, the maintenance work should pay attention to the following two aspects:

1.the CNC system should be regularly powered on and running idle, so that the heat from the electronic and electrical components of the CNC system can be used to dissipate the moisture inside the CNC cabinet

2.The normal supply of spare parts is a guarantee measure to ensure the normal and uninterrupted operation of the system. Our company will provide spare parts for auxiliary equipment during the warranty period and random spare parts during equipment installation and debugging

3.How do china aluminum parts cnc machining handle the cutting and carving processes of materials to meet the requirements of complex parts?

We operate our china aluminum parts cnc machining business with integrity and honesty.

1.Cleaning and inspection process

2.Measurement process

3.Adjusting the cutting space of the tool

4.How can china aluminum parts cnc machining cope with the manufacturing of non-standard or complex workpieces, such as reverse engineering or special shapes?

We have established a good reputation and reliable partnerships within the china aluminum parts cnc machining industry.

1.detailed design and modeling of the parts are required

2.Programming is a very important step in the machining process of CNC machine tools

5.How to ensure the dimensional accuracy of china aluminum parts cnc machining to meet assembly and splicing requirements?

We have a first -class management team, and we pay attention to teamwork to achieve common goals.

1. Use high-precision processing equipment and tools.

2. Strictly control the processing process.

3. Use appropriate testing for measurement work.

4. Conduct pre assembly coordination testing and adjustments

6.What is the accuracy and repeatability of china aluminum parts cnc machining?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance.

1.The smaller the difference between the actual position of parts or tools and the standard position (theoretical position, ideal position), the higher the accuracy. It is a prerequisite for ensuring the machining accuracy of parts.

2.The consistency of continuous results obtained by machining a batch of parts under the same conditions (on the same CNC machine tool, with different operating methods and using the same part program).

7.How can china aluminum parts cnc machining respond to voltage and power standards in different regions and countries?

For imported CNC machine tools and equipment, it is necessary to read the accompanying instructions clearly and connect them according to the instructions. Before powering on, it is also necessary to carefully check whether the input voltage and frequency are correct

8.What is the research and development capability of the factory?

CNC machine tool manufacturers have innovated in the structural design of machine tools. They designed a more compact, stable, and highly rigid structure by analyzing the basic principles of mechanical cutting and the motion characteristics of machine tools. This structure can improve the rigidity and stability of the machine tool, reduce the vibration, noise, and heat generated during high-speed cutting, and thus improve the processing quality and efficiency.

9.How does the manufacturing process and process of china aluminum parts cnc machining affect their quality and accuracy?

The manufacturing process and process of china aluminum parts cnc machining affect their quality and accuracy in several ways. First, the accuracy of the CNC machining process is dependent on the quality of the raw materials used. If the raw materials are of poor quality, the accuracy of the machined parts will be compromised. Second, the accuracy of the machined parts is also affected by the accuracy of the CNC machine itself. If the machine is not properly calibrated or maintained, the accuracy of the machined parts will be compromised. Finally, the accuracy of the machined parts is also affected by the skill of the operator. If the operator is not experienced or trained properly, the accuracy of the machined parts will be compromised.

10.How can china aluminum parts cnc machining adapt to different hardness and processing requirements of materials, such as steel or plastic?

During the machining process, attention should always be paid to the wear of the cutting tools, and severely worn cutting tools should be replaced in a timely manner to ensure the machining effect.

When adjusting cutting parameters, comprehensive consideration should be given to factors such as material hardness, cutting depth, and the shape of the workpiece being processed to achieve the best effect.

11.How can we ensure our information should not let third party to see our design?

We are willing to sign NDA effect by customer side local law and promising to keep customers data in high confidential level.

12.How can china aluminum parts cnc machining cope with applications in high vibration and impact environments, such as transportation equipment or vibrating screens?

Reduce the cutting force to the minimum;It is to enhance the static rigidity of the tool system or fixture with the workpiece as much as possible

13.What is the production capacity of china aluminum parts cnc machining, and can they meet the needs of large-scale production?

china aluminum parts cnc machining are mainly suitable for the following occasions: batch production: CNC lathes are suitable for large-scale and continuous batch production.

14.What is the corrosion resistance of china aluminum parts cnc machining and is it suitable for applications with corrosive media?

The ability of metal materials to resist the corrosive damage of surrounding media is called corrosion resistance and it is suitable for applications with corrosive media.

Related Products

custom cnc parts hongyongmachinery

custom machine hongyong machinery

machined parts Hongyong Machinery

Metal CNC Hongyong Machinery

c&c machining Hongyong Machinery

cnc cutting service hongyong machinery

cnc cutting services Hongyong Machinery

cnc lathe services Hongyong Machinery

Related Links

Category: Other products